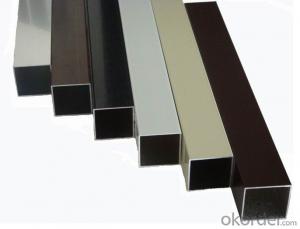

aluminium square tube

aluminium square tube Related Searches

1 Inch Aluminum Square Stock 3 4 Aluminum Square Stock 6063 Aluminum Round Bar Stock Fiberglass Pipe Shaver Pipe Scaffolding Aluminum Solid Square Stock 6063 T6 Aluminum Plate Square Aluminum Stock Aluminum Plate 6063 Polypropylene Pipe Size ChartHot Searches

Aluminum Square Stock For Sale Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale White Gazebo For Sale White Melamine Board Price Frp Price Per Square Foot Ceiling Fan Lowest Price Plywood Per Square Foot Price Cost Of Plywood Per Square Metre Aluminum Square Stock Near Me Cost Of Mdf Per Square Metre White Plastic Folding Chairs Wholesale Geotextile Fabric Cost Per Square Foot Frp Cost Per Square Foot Plywood Cost Per Square Meter Asphalt Shingle Prices Per Square Aluminium Wire Mesh Manufacturers India Ceiling Fan Lowest Price Aluminium Scaffold Planks Salealuminium square tube Supplier & Manufacturer from China

Okorder.com is a professional aluminium square tube supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest aluminium square tube firm in China.Hot Products

FAQ

- Yes, aluminum pipes can be suitable for wastewater systems. Aluminum is a lightweight material that is resistant to corrosion, which makes it a good choice for use in wastewater systems. It is also durable and can withstand high pressure and temperature conditions. Additionally, aluminum pipes are easy to install and maintain, making them a cost-effective option for wastewater systems. However, it is important to note that aluminum pipes may not be suitable for certain specific applications, such as in acidic or alkaline environments, as they may react with the chemicals present in the wastewater. In such cases, it is advisable to consult with a professional engineer or plumber to determine the most appropriate material for the specific wastewater system.

- What's the difference between an air conditioned pure copper tube and an aluminum tube?

- The copper tube has high heat transfer efficiency, corrosion resistance and good strength, but the price is expensive.The heat transfer efficiency of aluminum pipe is higher, the corrosion resistance is not good, but the price is much cheaper.

- Indeed, brewery equipment can utilize aluminum pipes. Aluminum, widely employed in the brewing sector, possesses numerous beneficial traits. Its lightweight nature, resistance to corrosion, and commendable thermal conductivity render aluminum pipes highly suitable for diverse applications in brewery equipment. These applications may involve fluid transfer, component connection, or heat exchanger construction. Nevertheless, it remains crucial to account for the brewing process's specific demands, including the beer type and the pipes' intended purpose, to guarantee their compatibility and appropriateness.

- How to control the hardness of aluminum pipe?

- The corrosion resistance is not high, in order to improve the corrosion resistance of anodic oxidation treatment and often used methods of paint or aluminum surface layer.

- aluminum tubes or iron pipes?Just bought oushennasi 62L small refrigerator (only a small box, frozen) to test what tube, took the magnet to the test, dry filter is iron, copper capillary, will also test where,Another: if it is iron, what does it matter?

- Since you bought it, you really don't need to know much about it. Even the aluminum tube is very durable.

- Automatic necking machine for aluminum pipe necking is what causes Hoove

- You can look at the Taizhou Federation of mechanical and electrical automatic CNC necking machine, CNC system to control the circular roller work, as if the effect can also be.If the pilot type relief valve, may be caused by not unloading overflow valve orifice plug through a relief valve.

- Aluminum pipe oval what reason?

- Can the United States control it? Don't issue so much Treasury debt and the United States has too much debt. Don't you worry that you can't afford a default?.

- Aluminum pipes, indeed, prove to be a fitting choice for underground installations. Their versatility and durability make them an ideal material for such applications. To begin with, aluminum pipes possess a lightweight quality that simplifies their handling and installation when compared to materials like steel or cast iron. This attribute not only reduces transportation expenses but also minimizes the requirement for heavy machinery during the installation process. Moreover, aluminum exhibits exceptional resistance to corrosion. It forms a natural protective oxide layer on its surface, rendering it highly impervious to rust and other forms of corrosion. This reliability makes aluminum pipes an excellent option for underground installations, where they will be subjected to moisture and varying soil conditions. Furthermore, aluminum is non-magnetic, making it appropriate for underground installations in areas where magnetic interference might be a concern, such as in close proximity to power lines or sensitive electronic equipment. Additionally, aluminum pipes possess commendable thermal conductivity, facilitating efficient heat transfer. This proves beneficial for specific underground applications like geothermal systems or underground heating and cooling pipes. However, it is crucial to note that aluminum pipes may not be suitable for every underground installation. Factors like soil conditions, water chemistry, and the presence of corrosive elements should be taken into account before selecting aluminum as the material for underground pipes. It is advisable to consult with a professional engineer or contractor experienced in underground installations to ensure the appropriateness of aluminum pipes for a specific project.